In an era where sustainability is a global priority, businesses are actively seeking ways to reduce their environmental footprint. Plastic manufacturing, often criticised for its ecological impact, is undergoing a transformation. At Denny Plastics, we are at the forefront of this change, offering innovative, sustainable fabrication solutions that minimise waste while maintaining exceptional quality.

The importance of sustainability in plastic manufacturing

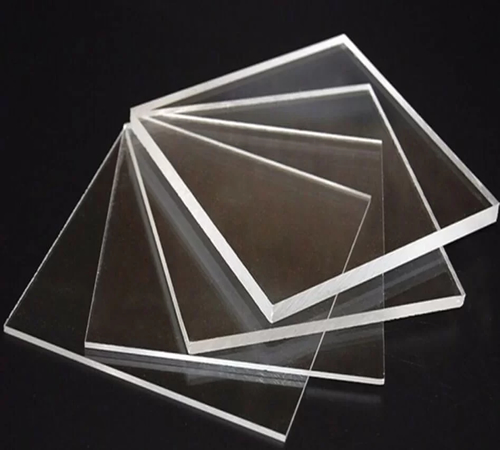

Plastic is a highly versatile material, but its production and disposal have significant environmental consequences. From resource consumption to pollution, the traditional lifecycle of plastic products poses challenges. However, by adopting sustainable practices, manufacturers can mitigate these effects and contribute to a greener future.

Denny Plastics is committed to sustainability, combining cutting-edge technology with eco-friendly processes to deliver solutions that meet the needs of environmentally conscious clients. Whether you’re an event organiser, caterer, or business owner, our sustainable fabrication methods can help you achieve your green objectives without compromising performance.

How Denny Plastics reduces waste in fabrication

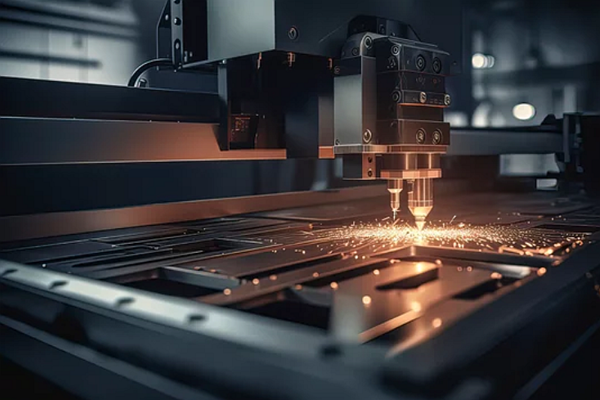

Precision cutting for maximum efficiency

A cornerstone of our waste reduction strategy is precision cutting. Using advanced machinery, we ensure that every cut is optimised to maximise material usage and minimise offcuts. This not only reduces waste but also lowers costs, making sustainability an economically viable option for our clients.

Recycling offcuts for a circular economy

Even with the most efficient cutting techniques, some offcuts are unavoidable. At Denny Plastics, we recycle these offcuts through an in-house process, transforming them into reusable materials. This closed-loop system guarantees zero waste, reinforcing our dedication to a circular economy and mitigating our environmental footprint.

Eco-friendly material options

We collaborate with clients to select materials that align with their sustainability goals. From biodegradable plastics to recycled polymers, we offer a range of environmentally friendly options that deliver durability and performance without compromising on eco-conscious values.

Why eco-conscious businesses choose Denny Plastics

For industries like event planning and catering, sustainability is no longer optional, it’s a necessity. Consumers and clients are increasingly prioritising green solutions, and Denny Plastics is here to help businesses meet their demands.

By partnering with us, you can:

- Reduce your environmental footprint

- Appeal to eco-conscious customers and clients

- Save on material costs through efficient fabrication processes

- Showcase your commitment to sustainability

Leading the way in sustainable plastic fabrication

At Denny Plastics, sustainability is at the heart of everything we do. We are dedicated to helping businesses reduce waste, conserve resources, and achieve their environmental goals. Whether you need custom plastic solutions for an event or durable products for your catering business, we provide eco-friendly options that don’t compromise on quality. Join us in building a greener future. Discover how Denny’s Plastics is revolutionising plastic manufacturing with sustainable fabrication practices.