At Denny Plastics, precision is at the heart of everything we do. Achieving flawless results in acrylic fabrication necessitates a perfect blend of technology and expertise. CNC routing is one such technology that has transformed the way we create high-quality acrylic products. In this blog, we’ll dive into the CNC routing process, its benefits, and how it elevates custom fabrication projects. We’ll also share a case study from Denny Plastics to showcase its real-world applications, appealing to DIY enthusiasts, designers, and industrial clients alike.

What is CNC routing?

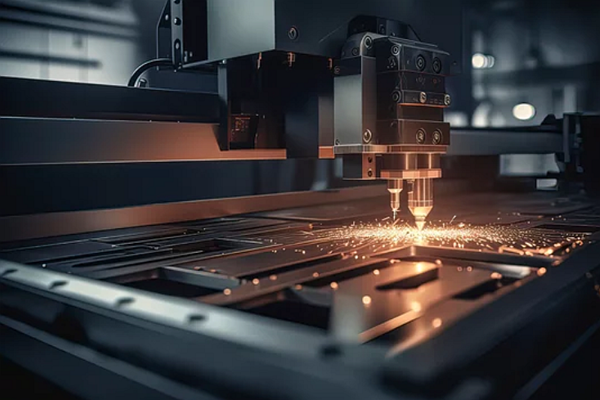

CNC (Computer Numerical Control) routing is a cutting-edge manufacturing process that uses computer-controlled machines to shape, cut, and engrave materials with exceptional accuracy. For acrylic projects, CNC routing is particularly effective due to its ability to handle the material’s unique characteristics, such as its brittleness and susceptibility to cracking.

The process starts with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into a set of instructions for the CNC machine, which uses a rotating cutting tool to precisely carve the acrylic into the desired shape. The result is a perfectly crafted product with intricate details and clean edges.

Why CNC Routing is Ideal for Acrylic Fabrication

CNC routing offers numerous advantages for acrylic projects, making it a preferred choice for custom fabrication. Here are some of the key benefits:

Unmatched Precision and Accuracy

CNC routers can achieve tolerances as tight as 0.1 mm, ensuring every cut and engraving is exact. This level of precision is crucial for creating complex designs and ensuring components fit together seamlessly.

Versatility in Design

From intricate engravings to large-scale cuts, CNC routing can handle a wide variety of tasks. It’s also compatible with different types of acrylic, including cast and extruded acrylic, offering flexibility in material selection.

Time and Cost Efficiency

Once the design is programmed, the CNC machine can produce multiple identical pieces quickly and consistently. This makes it ideal for both one-off custom projects and larger production runs, saving time and reducing costs.

Superior Finish Quality

CNC routing produces smooth edges and surfaces, minimising the need for additional finishing work. This is especially important for acrylic, where rough edges can detract from its clarity and visual appeal.

Case study: Turntable Base Replacement

One of our recent projects at Denny Plastics perfectly demonstrates the capabilities of CNC routing. A client approached us with a unique challenge: their vintage turntable’s base had cracked, and they needed a replacement that matched the original design.

Using CNC routing, we were able to recreate the base with incredible precision. Here’s how we did it:

- Scanning the original base to create a digital template.

- Designing the replacement in CAD software, ensuring it matched the dimensions and intricate details of the original.

- We are cutting the new base from high-quality cast acrylic using our CNC router.

- Polishing the edges to achieve a flawless, professional finish.

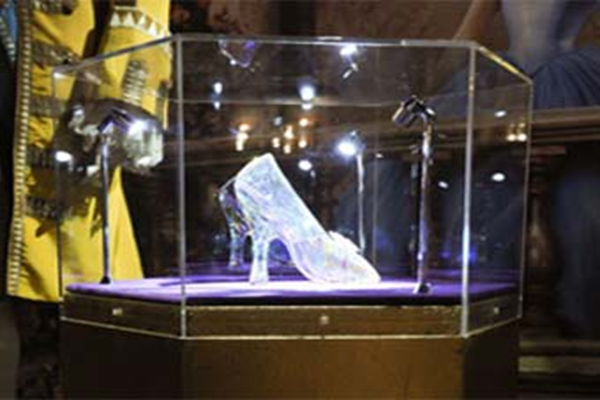

The result was a stunning replacement base that not only matched the original but also enhanced the turntable’s appearance with the clarity and elegance of acrylic. This project highlights how CNC routing can restore and improve cherished items, making it an invaluable tool for both restoration and custom fabrication.

Why Choose Denny Plastics for CNC Routing?

At Denny Plastics, we combine state-of-the-art CNC technology with decades of expertise in acrylic fabrication. Whether you’re a DIY enthusiast working on a personal project, a designer creating a bespoke piece, or an industrial client in need of precision components, we’re here to help.

Our commitment to quality and attention to detail ensures that every project we undertake meets the highest standards. Additionally, our ability to work with a wide range of materials and designs makes us the go-to choice for custom acrylic fabrication in the UK.

Start Your Next Project With Denny Plastics

CNC routing has revolutionised the way we work with acrylics, enabling us to create precise, high-quality products that exceed expectations. If you have a project in mind, we’d love to hear from you. Contact Denny Plastics today to discover how we can bring your vision to life with the art of precision.

Whether it’s a turntable base, a custom display, or a unique design, let us show you how CNC routing can make all the difference.